How Rice Packaging Machinery Work:

Introduction:

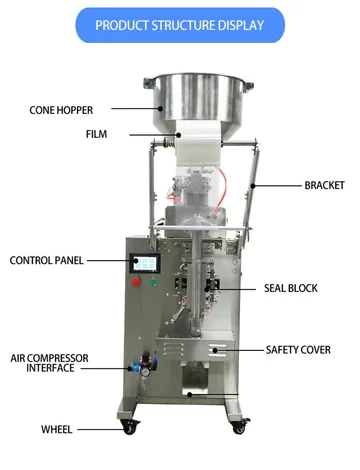

Rice packaging machinery is an automatic packaging machine for rice or grain. It can automatically complete the process from feeding to bag making, measuring materials, filling and bag making (ultrasonic sealing), printing lot numbers and cutting products. The main parts of this machine are as follows:

scale:

The most important part of the rice packaging machine is the scale use for filling. The scale has a large screen touch screen display. The electrical configuration adopts an imported PLC programming controller with a high degree of automation.

High precision in adjusting the filling rate makes it easy to adjust the material quantity according to actual volume requirement during the processing cycle; strong adaptability to materials makes it ideal for different kinds of raw materials like powdery materials

High-Level Functions of rice packaging machinery:

such as wheat flour beans etc.; an automatic control system is set up on board the computer with high-level functions such as save data records automatic without human intervention during the operation process so that no operator intervention is require after setting up operation mode which saves cost incurred in setting up different operational ways according to position.

Rice Packaging Machine Is A Special Filling And Sealing Machine For Packaging Non-Carbonated Drinks, Such As Fruit Juice And Tea Drinks.

A rice packaging machine is a special filling and sealing machine for packaging non-carbonated drinks, such as fruit juice and tea drinks. Rice packaging machines are used in the food industry to fill and seal non-carbonated drinks like fruit juice or tea.

Main Function Of A Rice Packaging Machine:

The main function of a rice packaging machine is to seal the bottle cap with an airtight cover while maintaining its original form after it has been filled with liquid or dry ingredients by simply pressing down on one side of each cap.

This Rice Packaging Machine Has The Advantages Of Stable Operation, Low Noise, No Pollution, Simple Operation, Convenient Maintenance And High Production Efficiency.

The rice packaging machine is a type of automatic packaging machine for rice or grain, which can package rice in different sizes and shapes. This machine uses ultrasonic sealing technology to seal the products after being processed by high-speed rotation and vibration.

It has an intelligent control system that automatically detects deviations from standard operation parameters during processing, such as temperature and humidity changes caused by ambient conditions (previous section). This ensures stable operation even when used under adverse conditions like extreme heat or cold temperatures.

Plc Control System of rice packaging machinery:

The PLC control system is relatively easy to learn because it only requires basic knowledge of electronics and programming skills; however, there may be special requirements depending on the user’s needs (e.g., size range). For example: if you have little experience with electronics but want something simple but effective then this product might be right up your alley!

The Filling Scale Adopts The International Advanced Pneumatic Measurement Control Technology.

The filling scale adopts the international advanced pneumatic measurement control technology. It can measure the volume of materials and other materials, such as:

- rice packaging machines;

- anti-explosion material packaging equipment;

- packing machines for medical products and drugs;

- chemical compound measuring devices (for example powder packing machine); etc.

The machine has many functions: it can measure the volume of materials, calculate the weight, calculate the amount of material and display the reading. It adopts advanced international pneumatic measurement control technology, which makes it convenient for users to operate and maintain.

The Control System Uses A Large Screen Touch Screen Display. The Electrical Configuration Adopts an Imported Plc Programming Controller With a High Degree Of Automation.

The control system uses a large screen touch screen display. The electrical configuration adopts an imported PLC programming controller with a high degree of automation. A PLC programming controller is a computer that controls the process of the machine, it can also be use in rice package machinery to control the process of the machine and make sure that it is work properly and efficiently.

The main functions of this system include:

- Shows information about each step in operation with a real-time monitoring system;

- Allows you to set various parameters according to your needs or requirements;

- Provides remote access through Internet so you can check out how your product performs from anywhere at any time;

High Precision In Filling Adjustment And Strong Adaptability To Materials.

the adjustment mechanism is especially strong, it can be adjust for different types of material. The filling amount can be adjust according to different package materials, such as paper bags and plastic bags.

The machine has a large number of adjustable parameters so that you can make your own products according to your needs and requirements.

Automatically Warning:

Automatically warns you if there is a problem with the machine; Provides statistical data of your product so you can analyze it and make improvements machine has a high degree of automation, which makes it easy to use and saves time. The rice packaging machinery is equipped with a complete set of standard accessory, such as a filling line, sealing machine and labeller..

The machine is easy to operate and has a high degree of automation, which makes it easy to use and saves time. The machine is equippe with a complete set of standar accessories, such as a fill line and seal machine Conclusion:

The above rice packaging machinery has the following advantages:

- It has been through a large number of tests and verification.

- Which means that it can be use for a long time without maintenance.

- It adopts an imported PLC programming controller with a high degree of automation.

- So that the operation is effortless and convenient.

- It can automatically complete the process from feeding to bag making, measuring materials.

- It can also be use to pack other kinds of non-carbonate drinks such as fruit juice or tea drinks