The Ultimate Guide To Filter Press Manufacturer In India

What is a Filter Press Manufacturer in India?

A filter press manufacturer in India helps you to make your filtration system more efficient and cost-effective by providing innovative, high-quality filters and filter presses. Filters are an important part of any filtration system as they are responsible for separating the solid particles from the liquid or gas stream. However, as the filtering medium, it replaced periodically or after each cleaning cycle to ensure clean water or proper filtration rate which depends on the kind of filter press being used.

The Types of Filters Available

Choosing a Filter Press Manufacturer In India determined by what your facility needs. There many types of filters, including activated carbon filters (which are good for odour control), spin-activated filters (which remove particulates), and gas-phase filtration (for removing VOCs). Depending on your industry, you other options to choose from as well. For example, thermal deodorization units often used in food processing plants to eliminate or reduce smells that can affect customers’ perception of quality. Once you decided which type of Filter Press Manufacturer In India works best for your purposes. it time to determine how big you need it to be.

How to Choose the Right Company?

When it comes to filtering press manufacturers, three basic maintenance steps must be completed regularly. These steps followed by anyone who owns one of these devices because they make your investment last longer and allow you to increase production over time. If you follow these steps, your filter press manufacturer should last for years. These steps washing, cleaning and greasing. The initial step when using your Filter Press Manufacturer In India is washing it thoroughly with water or hot water along with a mild soap or cleaning agent. In many cases, manufacturers provide specific instructions on how to clean their product so follow those instructions if they available. If not, any standard household cleaner should do just fine!

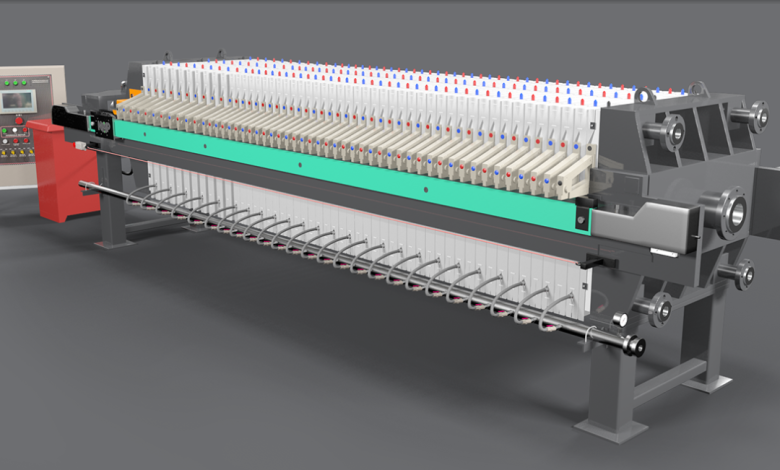

Parts and Components of a Filter Press

Many different parts and components make up a typical filter press machine. The following three main groups make up most of these machines: 1) plate, 2) frames and 3) pressure plates. The plates within these three groups consist of both an outer plate and an inner plate (usually made from stainless steel). These two types of plates must be perfectly flat and parallel to each other for a filter press to function correctly. They often connect through several joints, welds or bolts. In addition to having two plates on either side, Filter Press Manufacturer In India also have sealing screws that attach to those same frames that hold those two sets of plates together.

Maintenance Steps for Regular Use

A Filter Press Manufacturer In India user surprised at how much maintenance required on such a seemingly simple piece of equipment. To ensure your filter press remains free from clogs and other malfunctions. you need to remember these steps check filters daily (but not while they wet or dirty); keep filters clean; drain water lines regularly; check wear areas for sharp edges; oil lift gears every few weeks with SAE 90+ gear oil (do not use standard motor oil). keep motors dryer vent lines clear of debris/condensation/fungus; make sure all fittings airtight so pressure safely maintained.

It make sure there no leaks before power applied to new units—talk with manufacturer before starting up a new unit. In short, your Automatic filter press is like any industrial machinery—it will function best if it’s treated well and consistently maintained. It’s well worth that time spent caring for it since it can provide years of smooth operation.

Read about Lab Grown Diamond Rings